ESCIL has been a distributor of Well wire saws since 1987.

Over the years, we have acquired unrivalled knowledge and experience in the field of wire cutting. This is why we have been able to develop and boost the sale of machines and special custom-made supports and to accompany our customers in their purchasing procedures.

ESCIL participates in your market studies by offering to carry out validation tests in our laboratory. Our technicians are able to provide technical advice by telephone if necessary before any intervention to enable you to carry out your cuts more efficiently and to remain attentive to your needs.

Autonomous in our after-sales service, we intervene in our entire commercial sector and only follow the manufacturer’s recommendations. In order to guarantee the quality of operation of your equipment, only spare parts approved by the manufacturer are used.

We inform you that the wire saws sold by ESCIL must be used exclusively with consumables (cutting fluids, inserts, glues, reels of wire and wire refills) supplied by ESCIL in order to ensure optimal operation and to meet the machine’s warranty conditions :

- Diamond wire manufactured and approved by the manufacturer

- Original Well spare parts

- Cutting fluid approved by Well and ESCIL

- Checking and/or reconditioning of the drum, pulleys and coils

- Qualified assembly according to manufacturer’s recommendations

Innovation and Quality

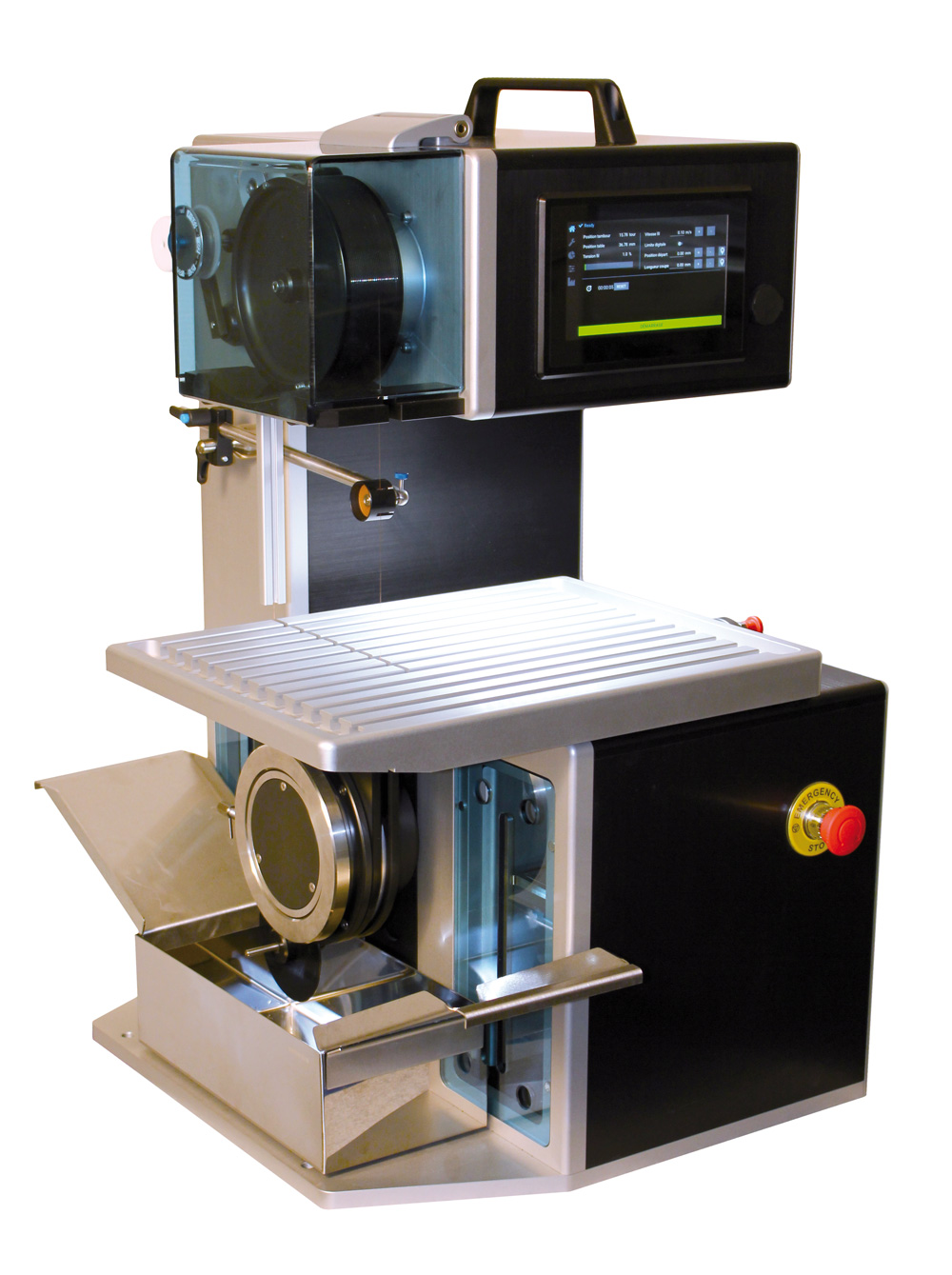

The new 3400 – 3500 – 4500 – 6500 – 7500 saws retain all the advantages of the 3000-6000 -7000 series that have made the success of these precision cutting machines worldwide for almost 50 years, integrating new technologies and superior performance with the best components available on the market for high quality production.

The machines

- The 3400 and 3500 series saws are designed for precision cutting of small samples and are very commonly used in laboratories because of their small size and their great simplicity.

- The 4500 and 6500 wire saws are designed for large samples with a passage up to Ø300mm. Despite the fact that they usually work on large workpieces, they are able to make cuts as accurate as the W3000 series if a fine wire is used.

- The 7500 saw offers the largest capacity of our range of wire saws and can adapt to your most demanding applications.

Consumables

Services

Our technicians regularly guide you in the use of your equipment, through constant telephone assistance. Our laboratory is at your disposal for any questions you may have concerning the feasibility of cutting your materials. We ensure the follow-up of your equipment by offering you the complete overhaul of your machines after a long period of intensive use.